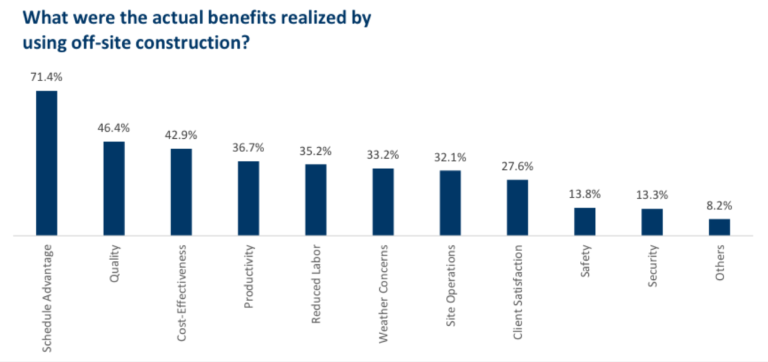

In this age of automation, the traditional model of constructing homes and buildings on-site is being more closely examined due to the waste, complex timelines, and inefficiencies. Modular buildings are gaining widespread acceptance as clients are looking to build in a fast, cost-effective and efficient manner. While requiring more robust upfront engineering and design, modular construction offers several advantages over conventional construction methods:

Time: In modular construction, teams are able to work in a controlled environment, using repetitive techniques and convenient equipment which has led to faster build times. It also reduces overall construction time and leads to more efficient scheduling as multiple production activities can occur in parallel. It’s estimated that modular building projects can be completed 30-50% quicker than traditional construction methods.

Quality Control: As approximately 80% of the build is carried out in a controlled environment, modular construction reduces exposure to unfavourable elements of nature and provides close access to all required tools and equipment. It also allows for a wider assortment of building materials and stringent quality control programs that lead to better-built structures and superior quality standards.

Improved Workflow: Efficiently designed manufacturing facilities result in the better sequencing of work, fewer deficiencies, less construction traffic, and safer installation processes. The modular construction approach also helps to improve communications at all levels of a project to ensure that information is exchanged in a timely and efficient manner.

Labour: According to a Construction Owners Association of America (COAA) study, 63% of direct labour time on mega-construction projects is spent waiting for materials and equipment, travelling to the area, taking early breaks, and planning how to do the work. With better work environments and defined processes, modular construction solves for many of these labour-related risks.

Cost Savings: There are a number of fixed costs that could be impacted by changes in environmental conditions of the site, leading to a lower return on invested capital. Through precision construction equipment and detailed designs in a controlled environment, modular construction is much less wasteful, has fewer unanticipated schedule disruptions and a lower probability of material theft or accidental damage.

Environment: Rather than discarding materials, waste in modular construction is generally used or recycled. As a result, the practice can help reduce the estimated 135.0 million tons of construction waste that ends up in landfills every year. Modular methodology uses substantially less time and energy than conventional construction – reducing the adverse environmental effects of the site itself.

We believe that the modular construction is at an inflection point, with a number of important applications stated above. There are a growing number of construction companies turning to modular construction to get the job done, however, there is scope for improvement. The construction business can be tough but if modular construction companies can crack the code, it could lead to a significant return for investors and efficiency gains in the space.

Disclaimer: While we use reasonable efforts to include accurate and up-to-date information, we do not represent, warrant or promise (whether expressly or by implication) that any Content (including any information sourced from third parties or estimates calculated by us) is or remains available, accurate, complete and up-to-date, free from bugs, errors or omissions or fit or suitable for any purpose. R-LABS Canada Inc., its shareholders, directors, officers, employees, representatives and agents will not be liable to you or any third party for any indirect, special, incidental, punitive, exemplary or consequential damages in connection with the use of this information.